Gear Shaping Tool Life Improvement Solutions

Passivation of HSS tools is extremely difficult with three main difficulties.

| 1 | Deburring of cutting edges |

| 2 | Passivation of cutting edges |

| 3 | No chipping |

If any of these three points are not dealt with properly, then the passivation of this HSS tool may be worse than if it is not passivated.

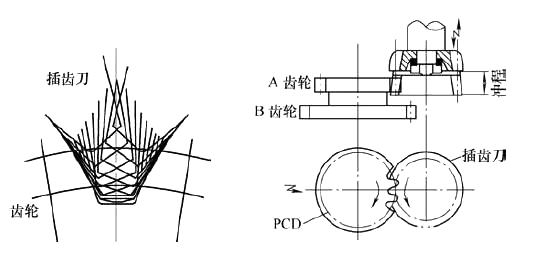

The material of the shaper is high speed steel. When inserting teeth, the up and down reciprocating motion of the shaper is the main cutting motion, and the speed of the motion is the level of cutting speed. In addition, the gears of the shaper and the workpiece mesh according to a certain speed ratio, which constitutes a circumferential feeding movement.

In order to increase the service life of the shaper, it is necessary to passivate the top teeth as well as the two side teeth in order to ensure that the cutting edge is removed during the cutting process.

Working Principle of Gear Shaping Cutter

ZOTEC's newly developed abrasives are ideally suited for passivation of HSS tools. We have been experimenting with the ZOTEC DF-3 machine and this newly developed abrasive. After measuring the edge passivation value with the machine, we obtained the following results.

| Passivation value before processing | Passivation value after processing | |

| crown tooth | 7.7um | 20.06um |

| left tooth | 7.3um | 19.1um |

| right tooth | 8.0um | 17.8um |

The processed values significantly extend the service life of the gear shaper, and the surface roughness of the processed gears is significantly improved.