Your Position:

» News

» Company news

» Deburring and Cleaning – B+...

Deburring and Cleaning – B+Z Advanced Materials Introduces DST-DEBURR Series Deburring Post-Treatment Neutral Aqueous Cleaners

Cleaning parts after deburring is an essential step, and the DST-DEBURR series plays a critical role in this process, which is why B+Z New Materials has decided to introduce the DST-DEBURR series. This article will explain how to use our tailored products to clean these parts. You will also learn why post-deburring cleaning is so important. But first, let’s start from the beginning and define what deburring is.

What Is Deburring?

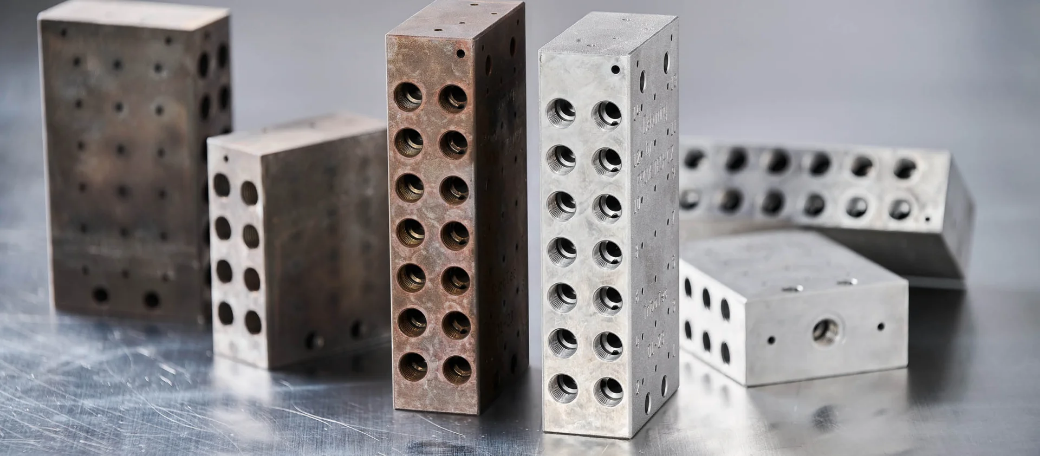

Deburring is the process of removing unwanted rough edges or protrusions (burrs) from metal materials, typically formed during machining processes such as cutting, drilling, or milling. Deburring enhances part quality by ensuring smooth surfaces, proper fit, and optimized performance, contributing to the functionality, aesthetics, and safety of the final product. In short, deburring is vital for maintaining quality, improving product performance, and enhancing overall functionality.

The Importance of Deburring in Manufacturing

Deburring is crucial across multiple aspects of manufacturing. First, it improves the functionality and performance of parts, ensuring seamless assembly and smooth operation. Additionally, it elevates the overall quality and aesthetics of the final product. Smooth, burr-free surfaces not only look professional but also minimize injury risks during handling or assembly.

By removing burrs, manufacturers can extend product lifespans, improve reliability, and ultimately boost customer satisfaction and loyalty.

We Are Experts in Post-Deburring Cleaning

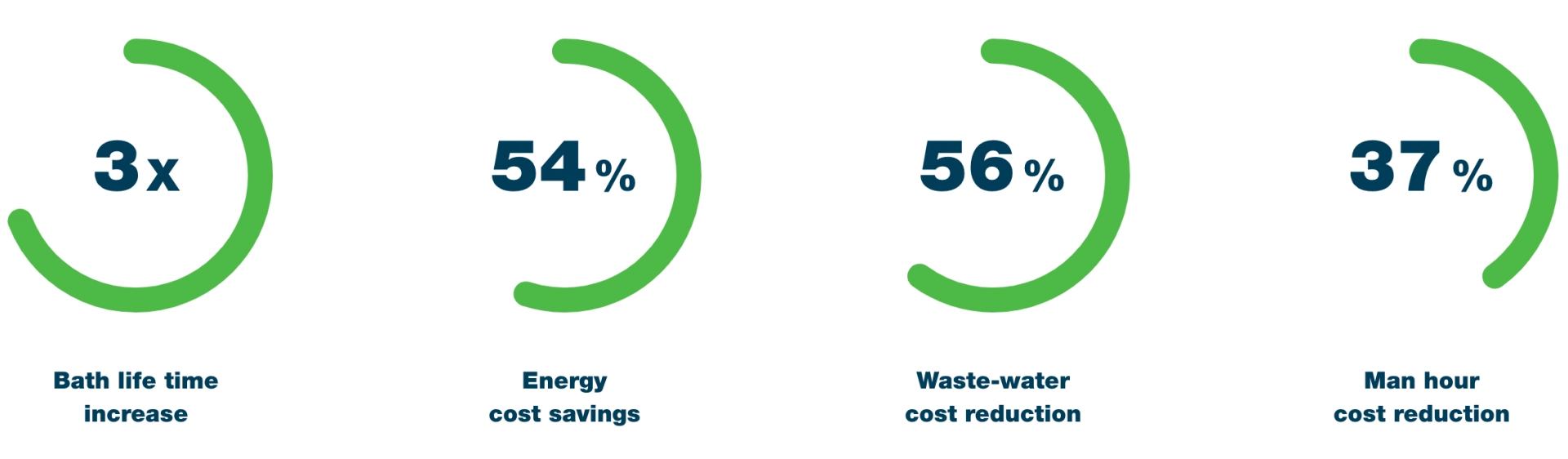

When it comes to post-deburring cleaning solutions, the DST-DEBURR series stands out as an industry leader. With 35 years of experience and expertise, we provide high-quality, powerful cleaning solutions specifically designed to clean oxide-covered surfaces after deburring while completely removing oxides during the cleaning process.

Compared to industry equivalents, the DST-DEBURR series delivers:

Deburring Processes

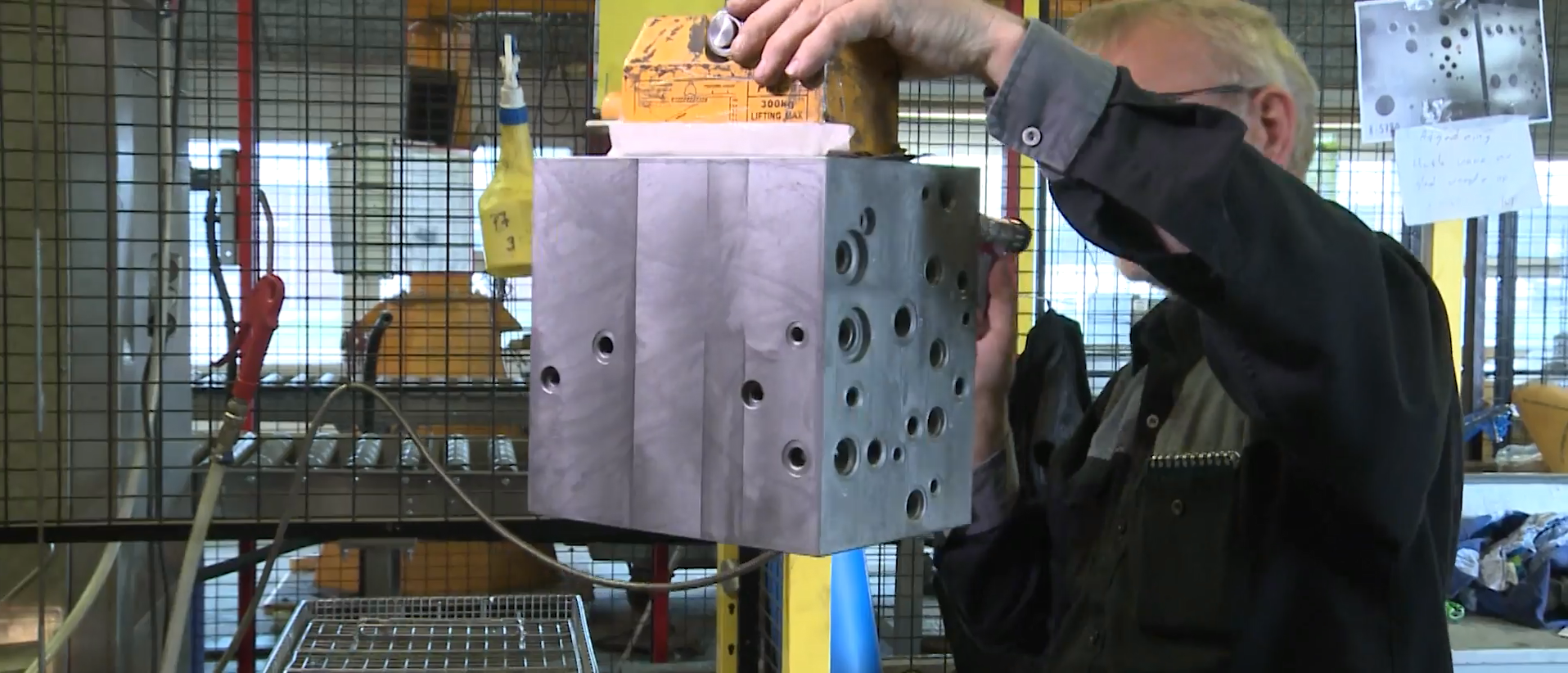

The DST-DEBURR series primarily provides cleaning products for post-Thermal Energy/Explosion Deburring (TEM) and Electrochemical Machining (ECM). However, the deburring method depends on factors like material type, burr size and shape, production volume, and required precision. Below are common deburring methods:

Manual Deburring

This involves handheld tools like files, grinding stones, or sandpaper. It suits small or delicate parts but can be time-consuming and labor-intensive.

Advantages

Cost-effective for small batches or one-off projects

Precise control over deburring

Ideal for fragile materials or complex geometries

Disadvantages

Time-consuming for large-scale production

Requires skilled labor, increasing costs

Risk of inconsistent results

Mechanical Deburring

This uses machines with rotating brushes, belts, or wheels for efficient, consistent deburring of larger parts or high-volume production.

Advantages

Faster and more efficient than manual methods

Consistent results for bulk processing

Lower labor costs

Disadvantages

High initial machine investment

Limited to parts within machine capacity

Risk of over-removal if not controlled

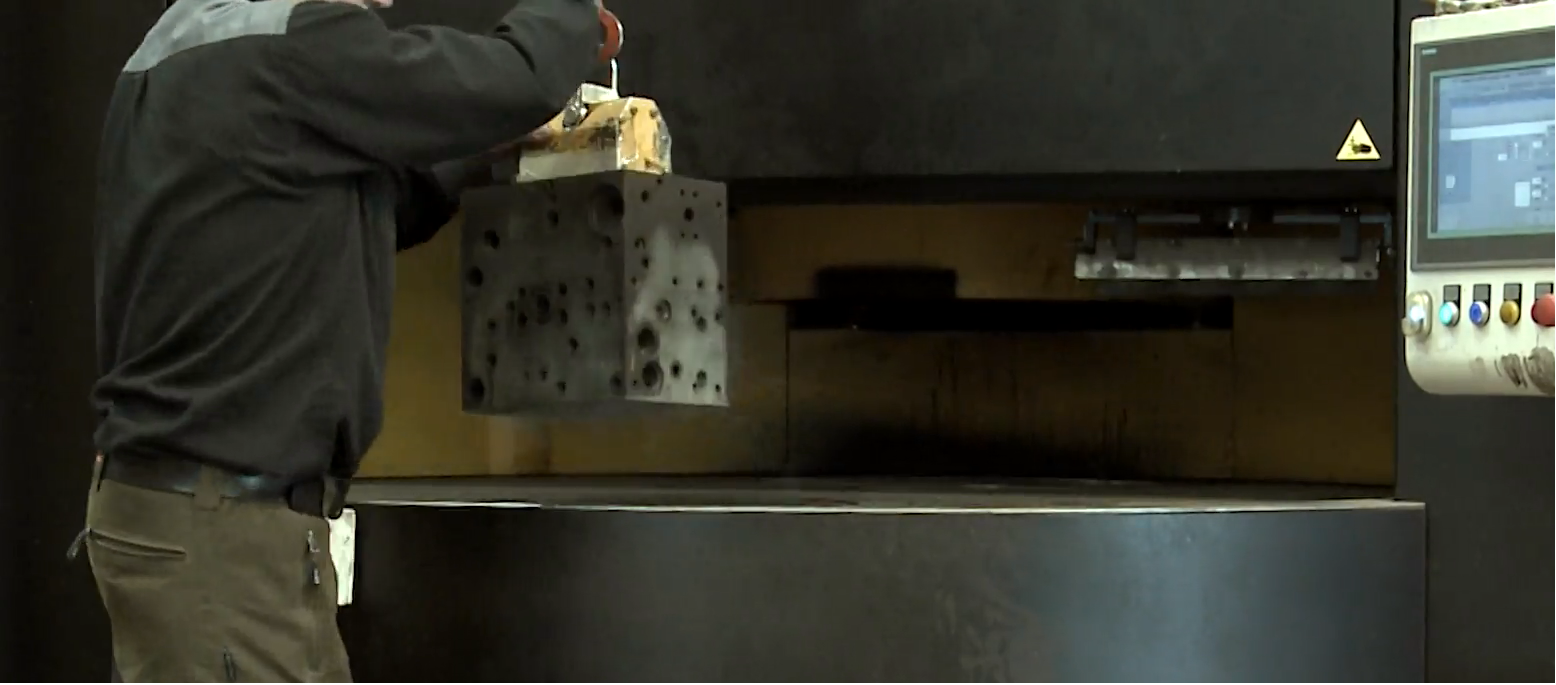

Thermal Energy Deburring (TEM)

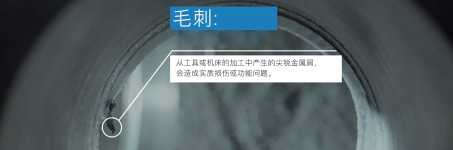

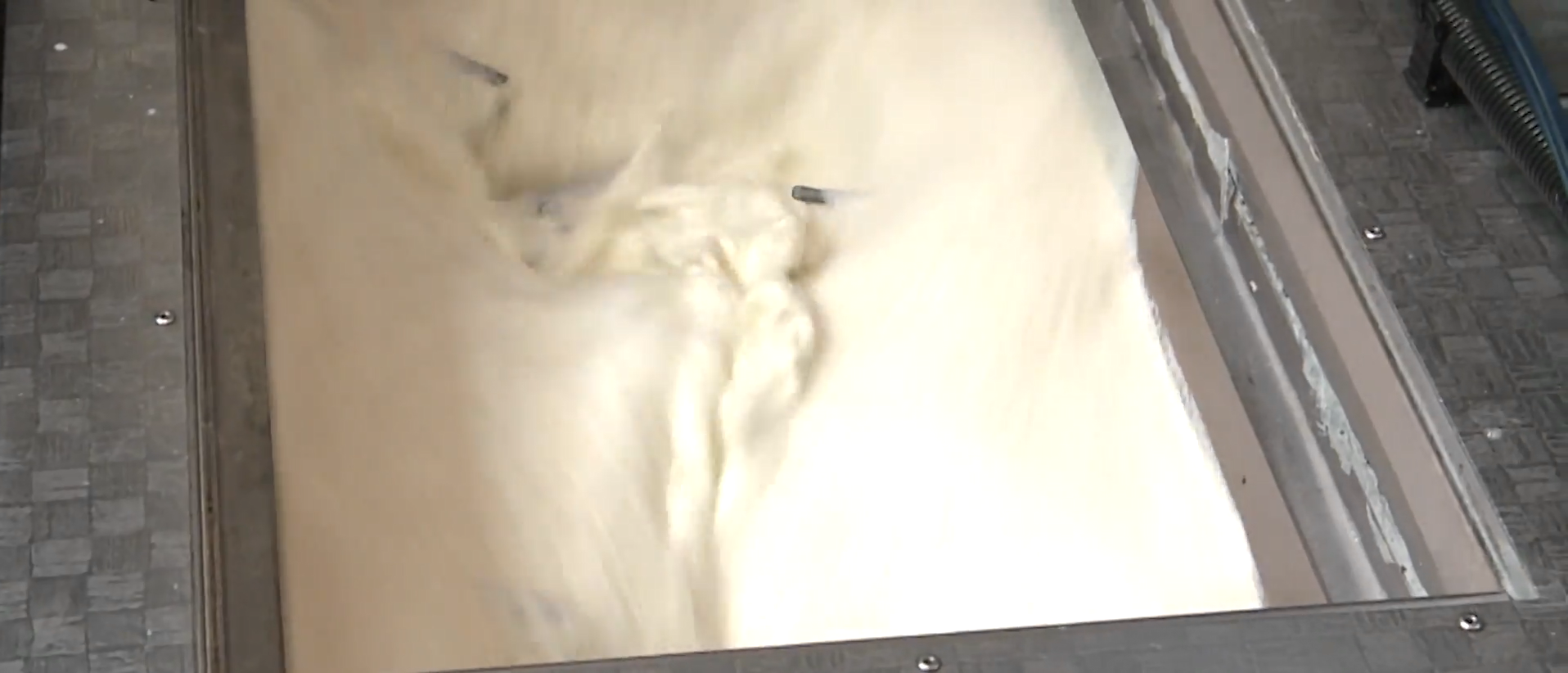

TEM uses combustible gas ignited in a pressurized chamber to vaporize burrs. Burrs, being smaller, combust instantly in an oxygen-rich environment, leaving an oxide layer that must be cleaned before further processing.

Advantages

Effective for complex or hard-to-reach areas

Suitable for various metals/alloys

High precision and short cycle times

Disadvantages

Safety risks from combustible gas

High equipment/operational costs

Potential surface discoloration/deformation

Electrochemical Deburring (ECM)

ECM uses electrochemical reactions to dissolve burrs without damaging surrounding material.

Advantages

Precise, controlled burr removal

Targets specific areas

Faster than manual methods

Low surface damage risk

Disadvantages

Limited for large or hard-to-reach burrs

Restricted to specific metals/alloys

High initial setup costs

Requires electrolyte maintenance

How We Guide Your Deburring Process

The DST-DEBURR series is a trusted partner in post-deburring cleaning, offering innovative solutions and expertise under our unique "Pure Performance Philosophy" to ensure top-tier quality and efficiency.

Our expert team has extensive experience in cleaning diverse parts and materials post-deburring. Knowledge of deburring techniques and chemistry enables tailored solutions for complex challenges.

Our "Pure Performance Philosophy" commits to optimizing every step of your process. Regardless of your deburring method, our cleaning products, process optimization, and quality control ensure superior results.

We collaborate closely with clients to analyze needs, conduct trials, and develop optimized processes, ensuring final cleaning exceeds expectations.

Why Post-Deburring Cleaning Is Essential

Post-deburring cleaning is critical, especially after TEM and ECM, for these reasons:

1.Removal of Contaminants: Deburring leaves debris, oxides, and loose particles. Cleaning prevents interference with downstream processes or equipment damage.

2.Surface Finish: Cleaning removes residues to achieve smooth, clean surfaces meeting specifications.

3.Corrosion Prevention: Residual chemicals/electrolytes from ECM can cause corrosion if not removed.

4.Avoiding Cross-Contamination: Residual particles can compromise coatings, lubricants, or assemblies.

5.Quality Assurance: Clean surfaces enable accurate inspection and process validation.

Overall, post-deburring cleaning ensures part integrity, minimizes issues, and guarantees smooth downstream processes.

Contact B+Z New Materials (Shanghai) Co., Ltd. today to experience superior deburring and cleaning solutions, and join us in building a greener, more efficient industrial future!