ZIMEX| brings aerospace surface treatment solutions to Turbinetech 2023 turbine technology conference

The 2023 Turbine Technology Conference was held from 25 to 26 May 2023 at the Hongqiao Greenland Convention Centre in Shanghai. The conference discusses advanced topics such as advanced intelligent manufacturing, high performance composite material production and application, low carbon energy power system construction, and discusses important and difficult topics on the road to efficient and intelligent development of aero-engine and combustion engines such as precision casting for aero-engine and combustion engines, advanced parts production and processing solutions, and design and implementation of high efficiency low carbon hydrogen gas turbines.

The

conference focused on the application and development of clean fuels in the

aero-engine and gas turbine sectors, and on the intelligent manufacturing of

aero-engines and gas turbines and the future market landscape. The conference

brought together over 560 representatives from the upstream and downstream of

the industry chain, including engine manufacturing, material production, blade

processing and gas power plants, and over 56 senior industry speakers to

discuss how hydrogen blended fuels can contribute to the decarbonisation of

aviation and gas turbines, as well as the technological progress and future development

direction of pure hydrogen-powered aircraft engines and gas turbines in the

context of the transformation of the national energy economic system.

Conference site

At this year's conference Zotec brings an integrated surface treatment solution of polishing, smoothing, rounding and deburring and a display of post-processing products. Highly efficient and reliable engineering is vital in the aerospace industry, where both the component and the production process need to meet demanding requirements for manufacturers. Zotec's flow rate machining solutions enable extremely low surface roughness to be achieved on the finished part, and chamfering and deburring processes for gears, discs and blades can significantly reduce engine friction.

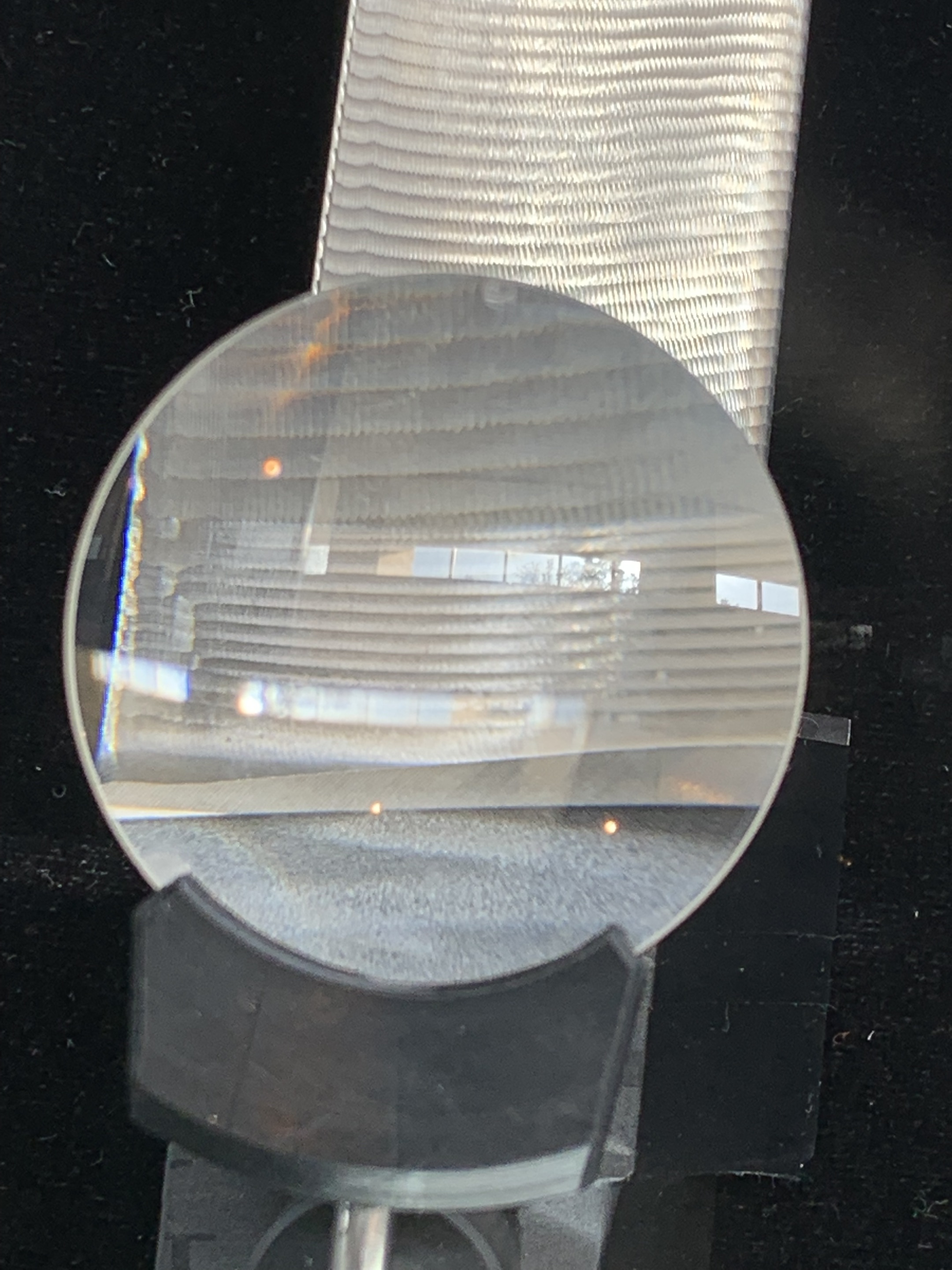

Before machining R.45µm

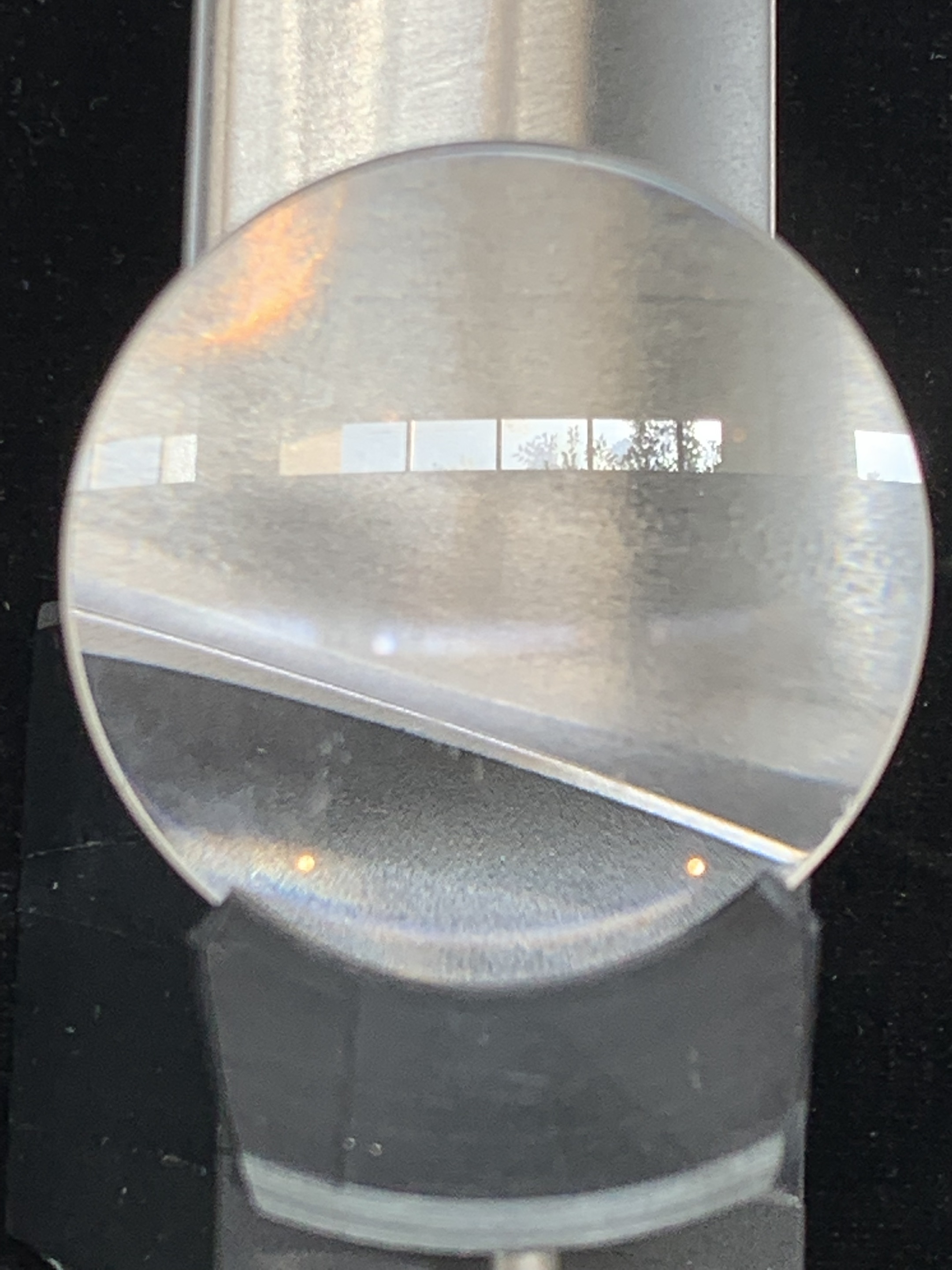

After machining R.24µm

Turbine blades work more efficiently with reduced friction on the part, longer service life and flatter milled groove surfaces. Zotec's process variation is as low as 1µm compared to other processes with a process variation of 5-10µm, and deburring and rounding of the part to a defined radius can be done in a single operation.

Detail of blade surface before treatment

Detail of treated blade surface

Currently, Zotec's DF drag polishers and SF flow polishers have a wealth of know-how and examples in processing components such as turbine and compressor blades, impellers and discs, servo valve assemblies, ball bearing components, blade roots, actuator components and gears. For more surface treatment solutions, we look forward to your inquiries and technical exchanges!